Industrial Equipment

Industrial equipment comprises the manufacturers of machines, tools, equipment or vehicles that are used to manufacture, extract, harvest or handle another product.

The growing trends of the 4th Industrial Revolution – automation, IoT, artificial intelligence, big data analysis, networked communications, machine learning and cloud computing – mark a significant change in the way we work and how we engage with our customers. These emerging technologies are providing advanced and disruptive Industrial Equipment solutions that support the creation, production and delivery of sophisticated and efficient machinery, equipment and components.

Customers

Below is a small selection of companies that use our products.

Plasma

- Burlington Automation

Marking

- Sisma

- Ortig

Robotics

- AIS Technologies

- Randek

- Fanuc

- KAWADA

- FUJI

3D Printing

- RegenHU

- Intech

- Materialize Dental

- Anisoprint

Pipe Bending

- Automated Industrial Machinery

Sheet Metal

- TRUMPF

- Schiavi

- Amada

- Salvagnini

Metal

- Hurco

- SACMI

- Weingärtner

- Agie Charmilles

- Fronius

- The Gleason Works

- Glaziers Center

Stone

- Donatoni Macchine

- Breton

Wood

- Homag

FAQ

Yes, when you load the DWG file in the Drawing workspace, layouts are available under the Drawing.Sheets property.

Want to see our products in action?

Watch the Made with Eyeshot videos playlist

Code Samples

Below is a selection of code samples related to these industrial sectors.

CamDemo

This sample explains how to create 2x and 3x toolpaths and simulate material removal. Video1

CheckCollision

This sample will demonstrate how to utilize collision detection.

CollisionDetection

This sample explains how to properly animate a robot arm and how to check collisions between objects. The additional tab is dedicated to 2D collision detection instead. For more details on the collision detection implementation, check this this article.

FeatureDetection

This sample explains how to detect features of a specific type on a 3D model. The filters allow narrowing down the number of cylinders or cones detected, and the "Show axes" button shows the cylinders' axis.

GCodeSimulator

This sample explains how to read a GCode file and simulate 3x CNC machining. Video1

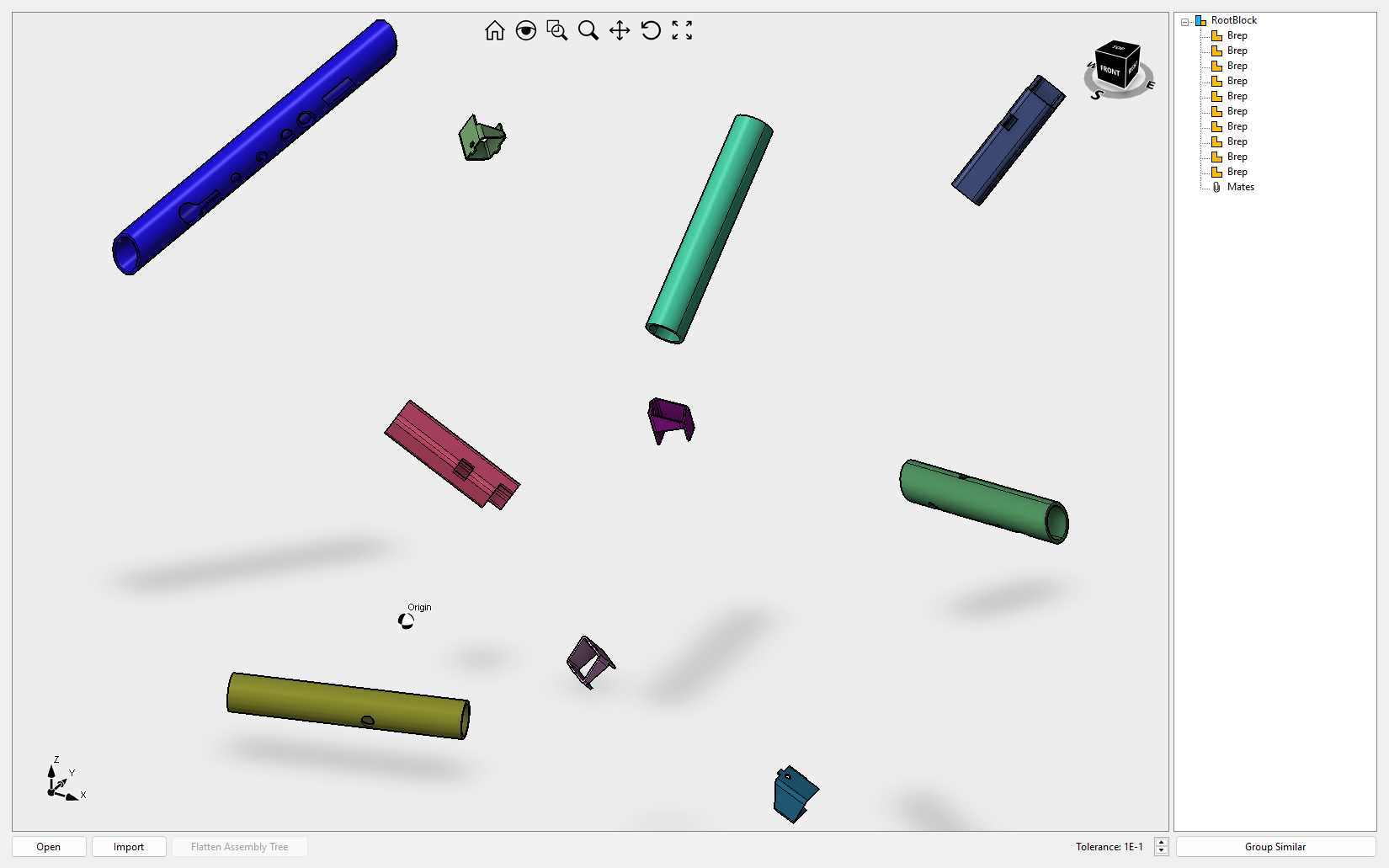

GroupSimilar

This sample explains how to use the FindSimilar class. Based on the invariant properties under roto-translation of 3D objects, this class can identify all 3D objects with the same shape and rebuild an assembly tree containing unique objects (mirrored included). Video1

MachineSimulator

This sample demonstrates how to simulate the movements of a 3-axis CNC machine. Initially, the moving components are loaded from STL files and incorporated into three distinct block definitions. Subsequently, three subclassed block references override the Animate() and MoveTo() methods to calculate the new position and move the objects (on GPU only). Additionally, it illustrates how to overlay drawings over all UI elements.

MeshEditor

This sample illustrates how to modify mesh triangles and vertices using the MeshEditor class. The available operations include edge flipping, edge collapsing, vertex dissolving for vertices connected to 3 or 4 triangles, vertex cell, and edge cell. Video1

PipeBending

This sample demonstrates how to simulate a pipe bending machine and inspect for collisions with surrounding objects.

PistonAnimation

This sample demonstrates how to animate a collection of entities.

WireEDM

This sample explains how to use the MultiFastMesh entity for machining simulations.