Direct Motion

Direct Motion uses Eyeshot to bring 3D CAD directly into its CNC software, removing the need for external CAM tools and significantly speeding up modern production.

February 05, 2026 | MANUFACTURING

About Direct Motion

Direct Motion, Inc. (DM) is a CNC control technology company based in the USA. We focus on CAD/CAM/CNC software and electronics to solve challenging manufacturing problems in the metal cutting and related industries.

DM produces powerful CNC control systems to power CNC machines featuring 4C, our Windows-based all-in-one system that integrates 3D CAD, CAM, CNC, and CMM into one complete ecosystem directly on the machine itself.

Direct Motion’s 4C software delivers a comprehensive design and manufacturing solution in a single, user-friendly package, eliminating the need for external software. Operators can program 3D solid models or import models directly on the machine’s 40" 4K touch display, then generate toolpaths on the 3D solid model and operate the CNC all from one location. This streamlines workflows from prototyping to production.

Eyeshot has allowed DM to integrate advanced 3d CAD directly into our product which provides a rich CAD/CAM environment to our customers directly on their CNC machine.

Jas Trounson, Lead Software Developer Direct Motion LLC

Challenge

Integrating Eyeshot into our platform marked a major shift in how users interact with their CNC machines. Before this enhancement, customers were forced to rely on external CAM systems to generate, adjust, and validate GCode toolpaths. Even the smallest modification required exporting models, switching applications, regenerating toolpaths, and re-importing files—a cycle that consumed valuable time and often introduced inefficiencies or compatibility issues.

This fragmented workflow made it difficult for operators to maintain momentum and increased the risk of errors during transitions between tools. Our goal was to eliminate these barriers and create a more fluid, intuitive experience.

By embedding advanced 3D CAD capabilities directly into the CNC environment, we aimed to give users the ability to import and create models, visualize them in detail, and refine toolpaths without ever leaving the software. The challenge was not only technical but also experiential: transforming a traditionally complex process into a seamless, integrated workflow.

Solution

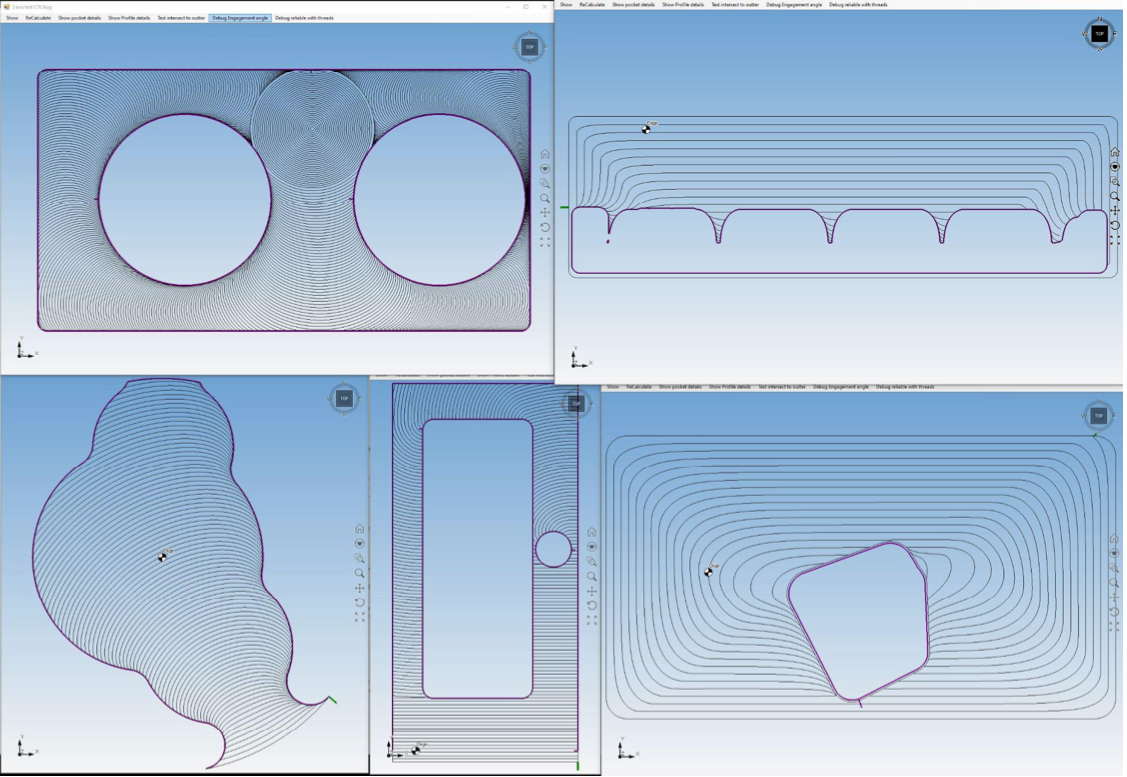

The integration of Eyeshot into our proprietary CNC software provided the foundation for a unified and highly efficient workflow. With Eyeshot’s advanced 3D engine embedded directly into the interface, operators can now import 3D models and manipulate toolpaths in real time, without relying on external CAM tools or regenerating GCode in separate applications.

This shift allows users to make immediate adjustments—whether modifying cutting depths, refining contours, or optimizing strategies—and see the results instantly within the same environment. The toolpaths generated or edited inside the software are immediately ready for machine execution, eliminating delays and reducing the cognitive load associated with switching between multiple platforms.

This streamlined approach not only accelerates preparation time but also enhances accuracy, giving operators greater confidence and control. The solution ultimately transforms the CNC workflow into a cohesive, end-to-end experience.

Results

The impact of Eyeshot’s integration has been both practical and strategic. Its native .NET compatibility allowed for a smooth and efficient implementation within our existing architecture, minimizing development friction and ensuring long-term maintainability.

Throughout the process, the Eyeshot support team played a crucial role, offering timely and knowledgeable assistance that helped us overcome technical challenges quickly. As a result, our customers now benefit from a more responsive, intuitive, and powerful CNC environment.

They experience faster setup times, fewer workflow interruptions, and a significant reduction in dependency on external CAM systems. The improved visualization and direct toolpath editing capabilities have also contributed to higher machining accuracy and reduced error rates.

Overall, the integration has strengthened our product offering and delivered measurable value to operators seeking a more modern and efficient CNC experience.

Testimonial

The integration of Eyeshot has transformed our product, bringing powerful 3D CAD functionality directly into the heart of the CNC workflow. Thanks to its seamless .NET compatibility, the implementation process was remarkably smooth.

Throughout the journey, Eyeshot’s fast and knowledgeable support team ensured every technical challenge was resolved without slowing us down. The result is a more powerful, efficient, and future-ready solution for our customers.

| Developer Name: | Jas Trounson | |

|---|---|---|

| Company Name: | Direct Motion LLC | |

| Product Name: | 4C Control | |

| Company Website: | www.directmotion.com |

Ready to Get Started?

Develop your CAD application with confidence with our .NET software components. Four different workspaces (the actual WinForms or WPF controls) are available to address common CAD workflows.

DOWNLOAD FREE TRIAL